OUR APPROACHES

DEVA started at the Agora in 2019. Our first aim was to create high-quality 3D models of several controversial inscriptions stored there. We knew we needed to address several challenges that previous researchers had yet to solve. Over several seasons, we developed effective methods to model marble inscriptions in 3D, at sufficiently high resolutions to enhance their legibility.

Researchers in the past had tried various kinds of projected-light scanners to digitize Athenian inscriptions in 3D. They encountered several discouraging problems.

CHALLENGES FOR 3D RDI

CHALLENGE #1: SCANNING REFLECTIVE, COLOURFUL MATERIALS

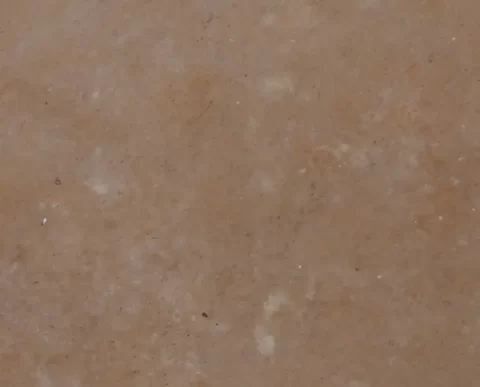

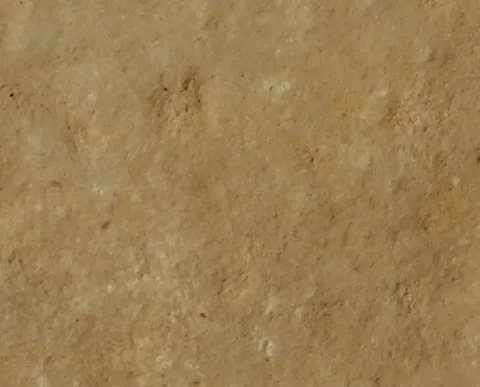

A first challenge for 3D recording is the marble itself. The crystalline surface is partially translucent and reflects light unpredictably. These material properties confuse most 3D scanners, which work by projecting a light pattern on a surface to observe how it is reflected back to the scanner. When the light pattern is refracted by the crystals, it can leaves gaps or produce a haze of inaccurate points obscuring the actual 3D surface.

Although there are methods to clean up these kinds of errors, they smooth over the data. This effectively reduces the scan resolution and can omit important details that are visible to the naked eye.

Another issue is colour. Most inscriptions were originally painted red so that the letters would stand out from the stone. Even when this paint has vanished, the grooves are often filled with accretions that similarly contrast with the stone. Most 3D scanners only record shape, but not colour, and so leave out potentially important information.

SOLUTION

DEVA has found some effective ways to get around these limitations. First, we minimize glare and reflection by using a polarized light source, set at a low angle so that it rakes across the surface. We set up one powerful lamp with a polarizing filter, and turn off all other sources. By rotating a second polarizing filter over the camera lens so that it matches the direction of the source, we can eliminate almost all the glare from the stone. The raking light increases the contrast of subtle features on the surface, which provides more information about the 3D depth.

The polarizing light removes reflections as if by magic, but it has drawbacks. The raking light is “baked” into the photographs, leaving parts of the surface in shadow and obscuring the colour. DEVA addresses these limitations by taking more than one pass. We move the polarized light to different angles, ending up with at least two and up to four sets with raking light. One final pass has lighting from the front, to minimize shadows and capture the colour accurately. We end up with at least three different sorts of lighting for each surface.

CHALLENGE #2: THE PROBLEM OF SCALE

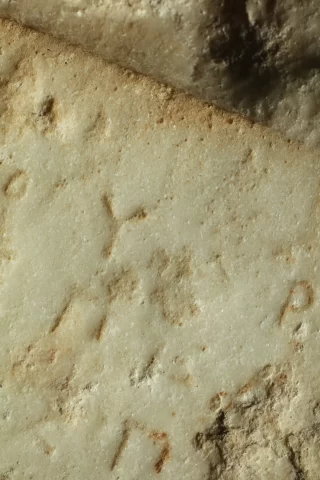

Athenians carved many laws, decrees, and accounts into marble steles set up in the Agora and other public places. Marble is expensive, and there was only so much space available to display these huge slabs. As a result, the letter-carvers tried to make the most of every stone by packing as many tiny lines of script as they could manage. This creates technical headaches for 3D scanning. On the one hand, the surface area can easily exceed a square meter of text, but the detail needs to be extremely fine to capture lettering as short as half a cm. That is, the letters are down to the size of a pinky fingernail.

An enormous number of 3D measurements are needed to capture the narrow strokes of these tiny letters, especially when they have been nearly scraped off the surface.

SOLUTION

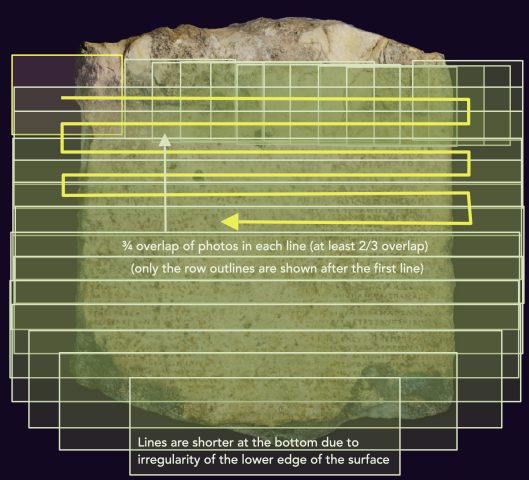

By capturing 3D information through photogrammetry instead of a laser scanner, DEVA has more flexibility in how it digitizes a stone. We are using a top-of-the-line 50 Megapixel camera with a medium-format Hasselblad lens in order to capture as much crisply focused information in each shot as possible. We adjust the distance from the stone so that we can see at least 20 pixels across each incised stroke.

CHALLENGE #3: REGISTERING SCANS TOGETHER

Registration is a formidable challenge. High-resolution 3D scanners are designed to capture data within a tiny region, which means that a large stele requires stitching together many separate scan stations. Not only can errors accumulate over a large surface, but the combined file can be so massive that it overwhelms most software designed to display and manipulate 3D data.

Photogrammetry software is designed to manage huge 3D datasets, but our complicated batches of photos can still accumulate errors.

SOLUTION

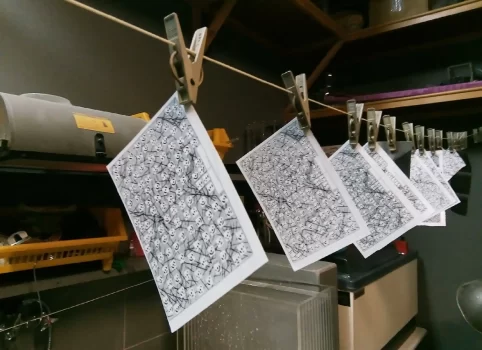

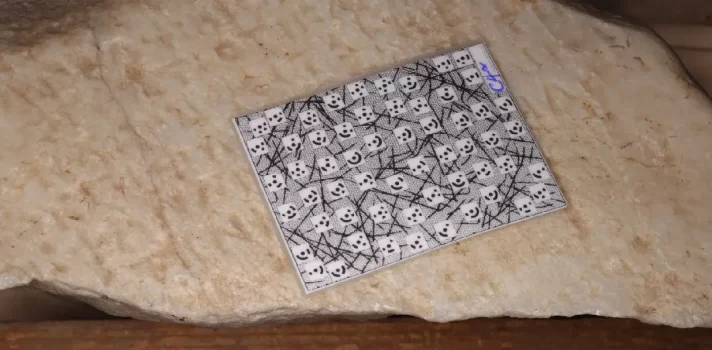

DEVA designed custom fields with machine-readable targets, which we place along the surfaces at strategic positions during photography. The fields help the software determine the relative locations of all the images.

The target fields are essential for unifying our sets of photos with different lighting. In photogrammetry, the computer finds thousands of distinctive features in each photograph and matches them to similar features in neighbouring photos. However, DEVA is deliberately changing the lighting direction in multiple passes. The photogrammetry software is seldom able to match the sets with different directions of raking polarized light, or the frontally illuminated colour layer. We rely instead on the machine-readable targets, which allow the software to link together and correctly align these different sets.

HOW RDI WORKS

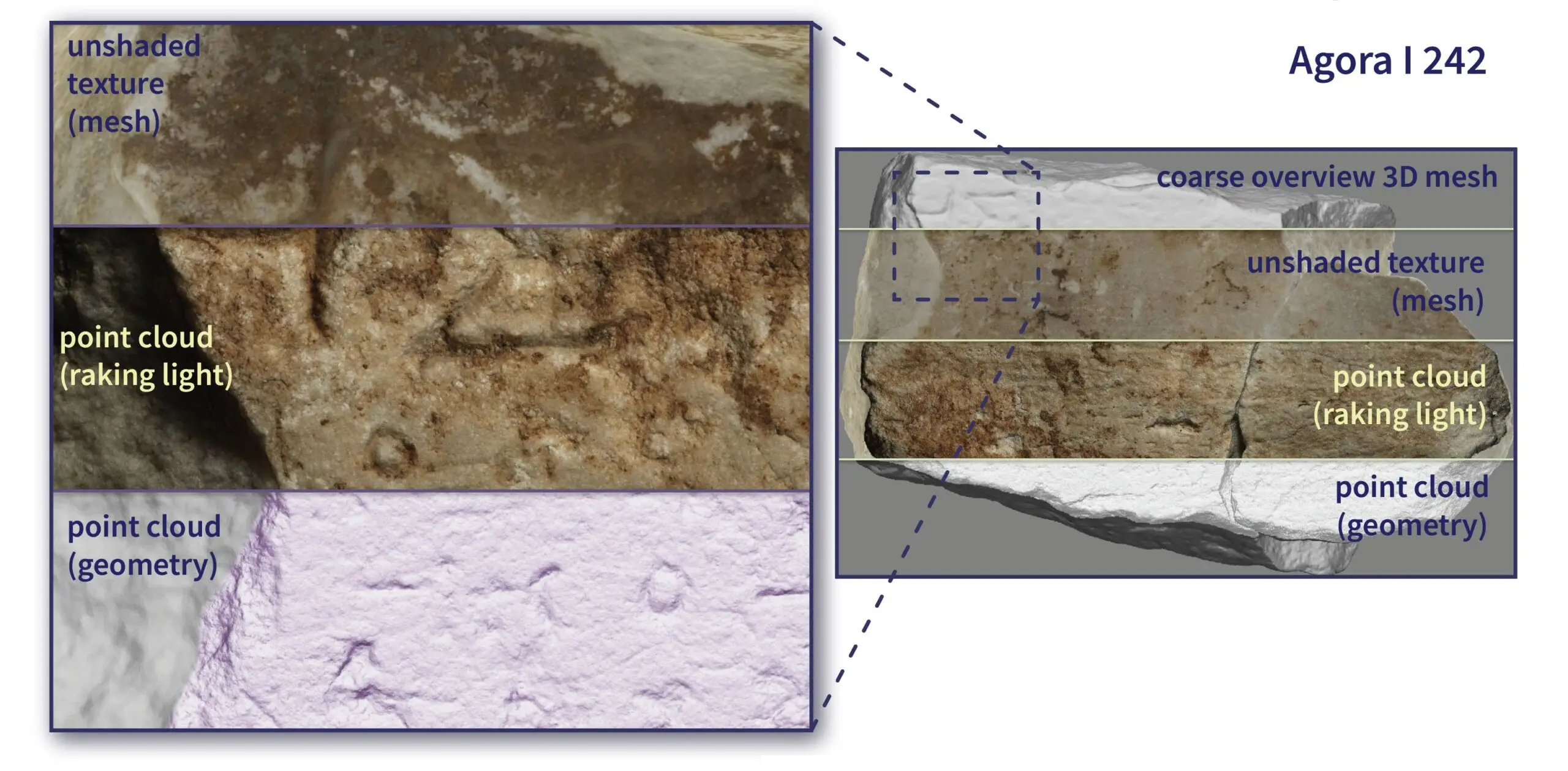

Relative Depth Imaging (RDI) is combination of methods that clarify the underlying geometry of an inscribed surface based on a 3D scan.

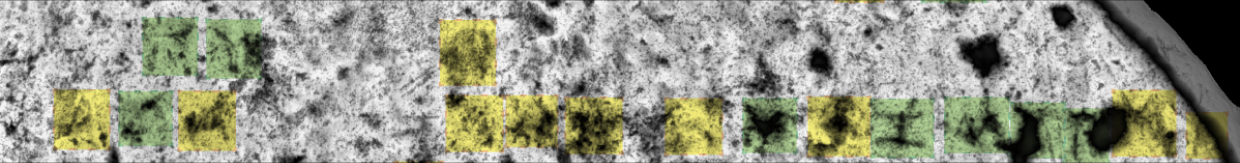

The imagery presents geometric information about the inscribed surface in a flattened 2D layer, combining visibility shading (ambient occlusion) with a non-photorealistic depth layer. The latter is set to grey or RGB values that emphasize features near the depth of the carved lettering, and which also distinguish regions where the surface has broken to a depth where no original text can have survived.

The Agora scans are built from multiple sources. First, DEVA has written new software that combines the 3D point clouds from multiple raking-light views. Since the scans are too large to display interactively in full 3D, the software renders a 2D image that contains depth and other spatial information saved in each pixel.

Primary data layers captured during

the digitization of Agora I 242

Second, the DEVA imagery includes other layers that complement the RDI shading. The user can fine-tune the sublayers within the RDI, and it is also possible to activate dynamic shading from a simulated raking light source, or to bring up the original colour.

The ancient text is most apparent in the RDI layers, but these alternatives are useful when trying to verify possible readings in the most difficult areas of an Agora stone. Occasionally the colour layer is the clearest representation. We find that flipping back and forth between the different styles of visualization is the most effective way to reconstruct an ancient text.

NEXT STEPS

DEVA is currently working on several of the Agora inscriptions, where the digital imagery has been confirming past hypotheses or leading to new insights. We are also planning new improvements in the source code which computes RDI and other layers. Our longterm objective is to develop a website that shares this imagery for all the digitized inscriptions from the Agora.

We expect that the techniques developed at the Agora for DEVA could be applied in many other scenarios. Similar inscriptions are found throughout ancient Greece, not just Athens. Hundreds of museums and archaeological sites have inscribed stones whose readings might be clarified through this kind of digitization. Our techniques would work with any incised medium, and there is no reason it couldn’t be applied for epigraphy of other languages and cultures. In fact, graffiti, reliefs, and any number of other kinds of incised artwork could benefit from these approaches to 3D recording and visualization.